We are constantly buzzing with ideas to make things better for our customers, and in the process, leading the pack in our industry.

We engage with our customers across the entire cycle from concept to commercialization, co-creating ideas, consulting on product & process, and hand-holding right through to the delivery of viable solutions.

Our Innovation teams lead research in areas such as barrier science, product resistivity, product migration, sealability, and regulatory compliance. Our Product Development teams then take this research forward, interacting with customers to provide appropriate solutions like structure finalization, colour, shoulder and cap type, and decoration possibilities. Based on approvals, we then develop mock-up samples and undertake stability studies with ingredient materials.

Glow in the Dark tubes are an exciting product offering by EPL – produced using highly specialized ink finishes on our tube surfaces. As suggested by the name, these tubes illuminate in part or whole, in the absence of any light source. For example, if a brand wants to emphasize its logo or any other USPs in the dark, Glow in the Dark tubes would be an apt solution.

Almost all of our laminate and plastic tube offerings can be customized to have this special luminous property, irrespective of diameter width and tube size. These tubes are particularly useful for clients in categories such as Beauty & Cosmetics, Pharma & Health, and Oral Care, and more so when unique packaging appeal is needed.

Glow in the Dark tubes are unique, instantly recognizable, and have high shelf appeal – perfect for when you need to make your packaging solution stand out versus the competitive set.

Super Titanium is a new tube alternative where “less is more” absolutely holds true. A key challenge with material source reduction is that it at times can lead to compromises with respect to packaging functionality. Developed with EPL’s family of next-generation polymers, the Super Titanium range of tubes addresses this by keeping input materials at a bare minimum without losing any of the key characteristic functional properties needed by clients. As such, Super Titanium tubes help in reducing the product’s carbon footprint, making it an eco-friendly choice when it comes to sustainable packaging. Super Titanium tubes also provide greater product stability, exhibit extended shelf-life properties and possess a rich exterior look and feel. It is especially well-suited for oral care, toiletries, and food products.

Offers a unique opportunity to reduce carbon footprint by less plastic usage while maintaining same product functionality

Send an Enquiry

Clarion is a high clarity UV shield tube. With this innovation your search for eye catching high clarity see through tube ends and enables brand visibility and lets your product do the branding for you. EPL’s Creativity & Innovation team know-how on raw material and process controls has been instrumental in developing a tube structure that provides glass-like clarity with UV shield properties between 175nm to 400nm. This Tube with UV shield, protects the content against rancidity and color fading. Elegant looking, high clarity tubes enable the filled product to see through with its natural color and texture thus attracting customer attention. Clarion tubes can be printed with high definition innovative graphics incorporating sensory elements. Clarion tubes have passed the stringent product stability tests at EPL laboratory and are found suitable for packing oral care, beauty & cosmetic products such as face wash, body wash, shampoo, conditioners.

Offers a high clarity see through tube with UV protection for your products to attract customer attention

Send an Enquiry

Today there is nobody in tube business that can offer this feature as it involved good printing technology and add-on eqipment to register the LENS FOIL to Print. EPL is the first to bring this technology to offer 3D LENS FOIL directly on the primary packaging. Today, it is all possible only on secondary packaging like CARTONS etc. By bringing this effect on Primary packaging (Tube), it makes the product go directly on the shelf without the need for secondary packaging (Saving Cost, time and more).

Offering Lens effects that are today available only on secondary packaging (which could be avoided)

Send an Enquiry

The Add-on on the best print technology allows EPL to add multi colour (up to 3) foils and even more on the tube directly. The add-on equipment also is a FOIL optimiser which saves foil consumption (Reuse up to 3 times) thereby reducing the carbon foot print by 75%. The multi colour foil + Foil over print allows us to offer our customer as many shades/colours on foil. IT GLITTERS THE BEST ON SHELF.

Offering Shelfshout with variety of foil with FOIL SAVER option at EPL as part of sustainability

Send an Enquiry

Typically the EMBOSS and DEBOSS effect is available on Cartons with dies (Male & Female). This option on our start-of-the flexo press makes a unique 3D emboss effect achievable in-line. The raised foil is one of its kind at EPL in tube business. Again, we aim at getting the decorations that are today available only on secondary packaging.

Offering 3D Metallic effects that are today available only on secondary packaging (which could be avoided)

Send an Enquiry

Screen effect enhances the brand/product name with a Braille effect. It also helps print Braile option for the blind (Especially in Pharma business). We can achieve Screen in varioys clours. This is again possible with EPL's state-of-the-art flexo presses available across all its units globally.

Offering Screen Braille effects / textures to highlight the brand

Send an EnquiryAt EPL, a large percentage of our revenues come from smaller players who do not have the technological reach and resources of a large multinational corporation. These customers, however, are just as keen to compete with extraordinary agility in their respective markets. EPL is the go-to partner for many such players globally, who rely on us end-to-end to make their branded dreams a reality.

Our upstream investments like EACT (Electronic Artwork Collaboration Tool) ensure that we are able to work with smaller clients quickly and digitally. Such productivity tools enable great precision, brilliant decoration, and quicker decision-making. We are also able to help smaller clients with advisory services, and where warranted, turnkey projects to get them going.

We believe in the old Japanese saying, “None of us is as smart as all of us”. And so, EPL partners with key clients to ensure that they can realize their product & packaging dreams quickly and effectively. Our teams work closely with client teams to define, design, develop, and deploy new ideas, so their brands can be first to the market where it matters more. Our recent development of organic laminates in the USA, our controlled dosage caps developed for cosmetics suppliers in Asia, and our henna tubes for South Asia are some examples of this. We look forward to partnering with more and more players to create packaging magic for them.

We have a simple, yet effective collaboration process as outlined below. This has proven effective in co-creating successful innovation for some of our most valuable clients.

01. Conceptual Discussion

02. Product Discussion

03. Customer Interest Confirmed

04. Product Testing Initiated

05. Technical Product Approval

06. Aesthetic Approval

07. Commercial

The wooden cap, printing and varnish have all contributed to the final look of this beautiful recyclable PCR tube for our customer.

With a very clear brief from the Happybrush team to prioritize sustainability, without compromising a single point on aesthetics, Our team, developed this tube with the Etain laminate.

The tube shoulder with a wooden finish cap gives a further distinguished look to the overall tube design.

The 35 dia tube, made from the recyclable Etain laminate, has the assurance of a strong barrier that keep the product safe throughout its lifecycle.

tube with its superior barrier properties ensures the best solution to the prime requirement of food packaging, i.e. safe filling and sealing.

Hela's ketchup tube is a perfect example of innovation meeting sustainability. Made with EPL's flagship APR and Recyclass approved sustainable laminate, Platina Pro, the

the slim flip top cap and shoulder that save one-third of the material compared to the traditional use.

An outstanding example of how sustainability and functionality can be seamlessly integrated, the Dove hand cream tube, made with 100% recyclable Platina laminate, uses

Packaged in a special tube structure, the overall look is a mix of tube design, print quality, and graphics. This product is available in a pack of 25g.

EPL is proud to partner with HipHop Skin Care for the launch of HipHop Hair Removal Cream with Charcoal for Women.

Packaged in a special tube structure for cosmetic application, the overall look is a mix of tube design, print quality, and graphics. This product is available in a pack of 100 g.

EPL is proud to partner with HipHop Skin Care for the launch of Hair Removal Cream for Men.

The pump tube closures are specially calibrated to dispense precise amounts of product content and the tubes were designed to have premium shelf appeal.

EPL is delighted to partner with Amway for the launch of its Skin Care Product Line.

EPL is happy to have partnered with Dot & Key by supplying it with Premium Look and Feel Crown Cap Closures for the launch of its High-end Skin Care products.

EPL is happy to have partnered with Dot & Key by supplying it with Premium Look and Feel Crown Cap Closures for the launch of its High-end Skin Care products.

EPL is happy to have partnered with Modicare for the launch of their SCHLOKA Skin Care products. All of these six products are available in different sizes of tubes.

EPL is happy to have partnered with Modicare for the launch of their SCHLOKA Skin Care products.

The design, graphics and print of the packaging tube have been designed to resonate with and attract the intended target audience. The product is available in a tube pack of 100ml.

EPL is delighted to partner with Himalaya Personal Care for the launch of Fresh Start Oil Clear Face Wash available in Blueberry.

EPL is delighted to partner with Amway for the launch of Attitude Be Bright Herbals Face Wash. The product is available in a tube pack of 100ml.

EPL is delighted to partner with Amway for the launch of Attitude Be Bright Herbals Face Wash.

EPL is delighted to partner with Himalaya Personal Care for the launch of their new Lip Balm. The product is available in 5g and 10g tube packs.

EPL is delighted to partner with Himalaya Personal Care for the launch of their new Lip Balm.

EPL is delighted to partner with Himalaya Personal Care for the launch of Fresh Start Oil Clear Face Wash available in Strawberry. The design, graphics and print of the packaging tube have been designed to resonate with and attract the intended target audience. The product is available in a tube pack of 100ml.

EPL is delighted to partner with Himalaya Personal Care for the launch of Fresh Start Oil Clear Face Wash available in Strawberry.

EPL is glad to have partnered with Medimix Ayurvedic in the launch of their new product range of body wash. Each product is available in a tube pack of 300ml.

EPL is glad to have partnered with Medimix Ayurvedic in the launch of their new product range of body wash.

EPL is delighted to partner with BEARDO for the launch of Activated Charcoal Peel Off Mask. Black has been maintained as the theme colour and this product is currently available in a tube pack of 100g.

EPL is delighted to partner with BEARDO for the launch of Activated Charcoal Peel Off Mask.

EPL is delighted to have partnered with Agorsa Gourmet for the launch of their Garlic Paste packed in EPL’s Special Food Packaging. The product is currently available in a tube pack of 100g.

EPL is delighted to have partnered with Agorsa Gourmet for the launch of their Garlic Paste packed in EPL’s Special Food Packaging.

EPL is proud to have partnered with Wingreens Farms for the launch of Schezwan Chilli Garlic Sauce, Sweet Chilli Garlic Sauce, and Peri Peri Ketchup. Each product is available in a tube pack of 100g.

EPL is proud to have partnered with Wingreens Farms for the launch of Schezwan Chilli Garlic Sauce, Sweet Chilli Garlic Sauce, and Peri Peri Ketchup.

EPL is happy to partner with Joy Personal Care for the launch of their skin fruits face wash range of products. Each product is available in tube pack of 21ml, 50ml, or 100ml.

EPL is happy to partner with Joy Personal Care for the launch of their skin fruits face wash range of products.

EPL is happy to partner the launch of Colgate Swarna Vedshakti Toothpaste. This toothpaste is currently available in a pack of 25g, 100g, and 200g.

EPL is happy to partner the launch of Colgate Swarna Vedshakti Toothpaste.

EPL is delighted to have partnered with Agorsa Gourmet for the launch of their Tomato Paste packed in EPL’s Special Food Packaging. The product is currently available in a tube pack of 100g.

EPL is delighted to have partnered with Agorsa Gourmet for the launch of their Tomato Paste packed in EPL’s Special Food Packaging.

EPL is proud to have partnered with Wingreens Farms for the launch of their Cheesy Chipotle & Jalapeno Sauces and Cheesy Ketchup. Each of these products are available in a pack of 100g.

EPL is proud to have partnered with Wingreens Farms for the launch of their Cheesy Chipotle & Jalapeno Sauces and Cheesy Ketchup.

EPL is delighted to have partnered with Agorsa Gourmet for the launch of their Ginger Paste packed in EPL’s Special Food Packaging. The product is currently available in a tube pack of 100g.

EPL is delighted to have partnered with Agorsa Gourmet for the launch of their Ginger Paste packed in EPL’s Special Food Packaging.

EPL is proud to have partnered with Wingreens Farms for the launch of Tandoori Sauce and Achaari Sauce. The product is available in a pack of 100g.

EPL is proud to have partnered with Wingreens Farms for the launch of Tandoori Sauce and Achaari Sauce.

EPL is proud to partner with Bombay Shaving Company with the launch of Face Cleanser. It is a new concept design crafted in a packaging tube to complement the preference of the target audience with new graphics and print. The product is available in a pack of 100g.

EPL is proud to partner with Bombay Shaving Company with the launch of Face Cleanser.

EPL is proud to partner with Bombay Shaving Company with the launch of Face Moisturiser. It is a new concept design crafted in a packaging tube to complement the preference of the target audience with new graphics and print. The product is available in a pack of 100g.

EPL is proud to partner with Bombay Shaving Company with the launch of Face Moisturiser.

EPL is proud to partner with Amway India for the launch of Attitude Clear Activ Pimple Control Spot Corrector. Packaged in a special tube structure for cosmetic application, the overall look is a mix of tube design, print quality, and graphics. This product is available in a pack of 9 g.

EPL is proud to partner with Amway India for the launch of Attitude Clear Activ Pimple Control Spot Corrector.

EPL is delighted to serve as the partner for the launch of BEARDO’s Activated Charcoal – Acne, Oil & Pollution Control Face Wash. Packaged in an EPL tube with a special face wash structure, with a flip-top cap, and black as the tube’s theme colour – for an attractive look and feel. This product is currently available in a tube pack of 100ml.

EPL is delighted to serve as the partner for the launch of BEARDO’s Activated Charcoal – Acne, Oil & Pollution Control Face Wash.

We are Happy to Partner the Launch of Procreme which is a probiotic derived versatile formulation with peptides and growth factors which moisturizes, reduces pore size & wrinkles, fights hyper pigmentation and firms the skin.

Packaged in a Special Cosmeceutical Laminate and complemented by the Black Colored Flip Top Cap, the Look of Product comes out Elegant and Chic. Procreme is currently available in a pack of 100gm.

We are Happy to Partner the Launch of Procreme which is a probiotic derived versatile formulation with peptides and growth factors which moisturizes, reduces pore size & wrinkles, fights hyper pigmentation and firms the skin.

We are Happy to Partner Amway for their launch of Attitude Moisturizer for Oily Skin ,which is packaged in a Pump Tube. EPL’s Pump Tube is a high quality cosmetic application Pump ,which enables easy and measured dispensing of the liquid product. Developed through modern technology this product ,dispenser and graphics look superior in total. Currently this Moisturizer is available in a pack of 45ml.

We are Happy to Partner Amway for their launch of Attitude Moisturizer for Oily Skin ,which is packaged in a Pump Tube.

Beardo is a men’s grooming brand having a diverse portfolio of products. This product is packaged in a special cosmetic structure with an easy to use flip top Cap , with black being the core color of the product. The combination of black and yellow colors are adding to the product sophistication .This product is currently available in a 100gm pack.

Beardo is a men’s grooming brand having a diverse portfolio of products. This product is packaged in a special cosmetic structure with an easy to use flip top Cap , with black being the core color of the product.

We are happy to partner with Gravitale Revitalizing Skin Gel for its launch. Gravitale is an intermittent use exfoliant created with actual crushed grapes. The look of the product is designed to complement the naturalness of the product. Packaged in a special structure, a transparency element, enhances appearance. Gravitale is available in a 200 gram pack.

We are happy to partner with Gravitale Revitalizing Skin Gel for its launch.

EPL and Faber-Castell are proud to present for the first time water colour in tubes. These water colour product designs are a combination of super fine printing on smaller diameters, making the product extremely easy to use and carry around by artists. This travel friendly pack, which is sure to surprise artists, especially kids, is available in a pack of 5ml and 9ml.

EPL and Faber-Castell are proud to present for the first time water colour in tubes.

Creates a rich, creamy lather that lubricates your face to maximize the experience of shaving. Packaged in a special shave care plastic tube, the look of the tube is a combination of white and Turkish-green colour. In addition, it is given a matt effect to provide a premium look.

Creates a rich, creamy lather that lubricates your face to maximize the experience of shaving.

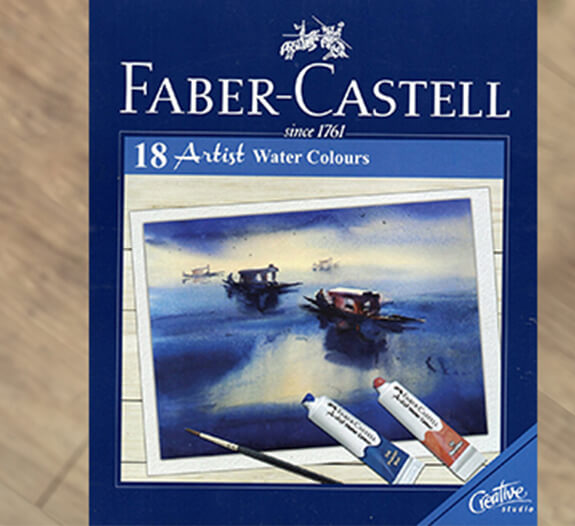

SPRIG NAM PRIK PAO, is a classic thai chilli Paste. The look of the product is a combination of sophisticated printing technology and is designed to complement its usage. It is packaged in a special food grade plastic tube, has been given a Matt finish to enhance product feel.

SPRIG NAM PRIK PAO, is a classic thai chilli Paste. The look of the product is a combination of sophisticated printing technology and is designed to complement its usage.

Sprig Mole is a Classic Mexican style spicy paste. It is packaged in a special food grade plastic tube, with a matt effect, making an all-round rolux tube. EPL is proud to have partnered in packaging this aggressive and unique food product.

Sprig Mole is a Classic Mexican style spicy paste. It is packaged in a special food grade plastic tube, with a matt effect, making an all-round rolux tube.

This tube features a salmon treat and training paste for your favorite pooch. It utilizes a plastic barrier laminate that was custom constructed to maintain the stability and product freshness for this one of a dog treat in a squeeze tube. Bright and bold colors make this a shelf standout along with a printing technique that adds fading in.

This tube features a salmon treat and training paste for your favorite pooch. It utilizes a plastic barrier laminate that was custom constructed to maintain the stability and product freshness for this one of a dog treat in a squeeze tube.

Wasabi is a vital part of Japanese cuisine. SPRIG Wasabi paste by Intergrow foods & beverages Pvt. Ltd, adds a delightful bite to the dish. It is savored along with traditional Japanese sushi platter or with sushi rice. EPL’s special transparent tube enables a clear view of the clean product inside. To keep this product fresh it is packaged in a compatible special tube.

Wasabi is a vital part of Japanese cuisine. SPRIG Wasabi paste by Intergrow foods & beverages Pvt. Ltd, adds a delightful bite to the dish.

Elois Hair Removal Cream is a depilatory which caters to a wide array of skin types like normal, sensitive and dry. It is packaged in a special laminated tube with superior barrier properties which is used specifically for hair removal creams. The laminate type and the cap types are specifically designed to enhance overall product appeal. Currently this cream is available in three variants – Aloe Vera, Papaya and Rose Essence.

Elois Hair Removal Cream is a depilatory which caters to a wide array of skin types like normal, sensitive and dry. It is packaged in a special laminated tube with superior barrier properties which is used specifically for hair removal creams.

The Fruttini range, a brand by Mann & Schröder, is a new customer launch in the Europe region, that we are proud of in the Beauty & Cosmetics category. Fruttini tube packs are manufactured using our Elite printing technology and are now available in more than 20 variants. The key benefits of these new tube packs is effortless dispensing and pack graphic quality.

The Fruttini range, a brand by Mann & Schröder, is a new customer launch in the Europe region, that we are proud of in the Beauty & Cosmetics category.

YouthRx is a new range of products from Lotus Herbals. This product is mainly for skin applications and hence resulting in a clear, smooth more youthful looking complexion. The Tube structure and the cap type give the product a differentiated look and feel and is developed on EPL’s patented Egnite Laminate and is currently available in a pack size of 100g.

YouthRx is a new range of products from Lotus Herbals. This product is mainly for skin applications and hence resulting in a clear, smooth more youthful looking complexion.

Saky is a local toothpaste brand in China that has enjoyed market success over the last year. Saky Kids® Children’s Toothpaste has specially been formulated as a high quality oral care solution for children, necessitating the need for EPL iShine® 3D Printing technology through which we have developed a 3D textured pack allowing for an exhilarating sensory touch experience for children when they hold the tube, encouraging them to brush their teeth.

Saky is a local toothpaste brand in China that has enjoyed market success over the last year.

For the first time in India, EPL is proud to have packaged the new Soul Ginger Garlic Paste, a product by ADF Foods, in the Food Category. This product is packed in a laminated tube developed on a special food grade laminate, with a multi-colour print and an easy to squeeze pack. Soul Ginger Garlic Paste is currently in the market in three variants: Garlic, Tamarind Pulp and Garlic Paste with Oil.

For the first time in India, EPL is proud to have packaged the new Soul Ginger Garlic Paste, a product by ADF Foods, in the Food Category.

The Thrive Natural Care Face Wash & Energy Scrub is a new customer launch that we are proud of in the Beauty & Cosmetics category, made of a potent blend of Costa Rican medicinal plants. The pack tubes are composed of a laminate structure that keeps the product fresh and invigorating for the consumer. It is decorated with an amber flood coat and a texture on Thrive’s brand feather, which adds a unique element to this package and makes it stand out in the shelf.

The Thrive Natural Care Face Wash & Energy Scrub is a new customer launch that we are proud of in the Beauty & Cosmetics category, made of a potent blend of Costa Rican medicinal plants.

The classy and elegant appearance of the new AGE Therapy Gel tube features simple and yet intriguing artwork that combines gloss and matte coatings to achieve a checkerboard look. The technique used creates unique appeal and provides tactility in the hands of consumers. The extrusion process and the materials used makes post-consumer recycling easy, while maintaining the product inside. It is a lightweight solution that allows for effortless dispensing of the product.

The classy and elegant appearance of the new AGE Therapy Gel tube features simple and yet intriguing artwork that combines gloss and matte coatings to achieve a checkerboard look.

It’s flavored vodka in a tube! For the Go Wodka Extreme tube we achieved an eye-popping display that places youthful and vibrant colours on a background created with a metallic sheen. The silver finish is actually built into the laminate and manages to truly bring out the graphics and text to the fore. In order to hold the right measure of liquid, the tube had to be made longer than normal (204mm/8.3in).

It’s flavored vodka in a tube! For the Go Wodka Extreme tube we achieved an eye-popping display that places youthful and vibrant colours on a background created with a metallic sheen.

The TRESemmé Keratin Smooth shampoo and conditioner tubes are made using EPL’s trademark Egnite laminate that consists of a multilayer, high- luster structure. The combination of the glossy finish and burgundy colour really makes the tube shine from the shelf. The metallized, reflective glaze is achieved using plastic based materials that provide excellent ‘bounce back’ characteristics, helping the tube retain its shape when squeezed and released.

The TRESemmé Keratin Smooth shampoo and conditioner tubes are made using EPL’s trademark Egnite laminate that consists of a multilayer, high- luster structure.

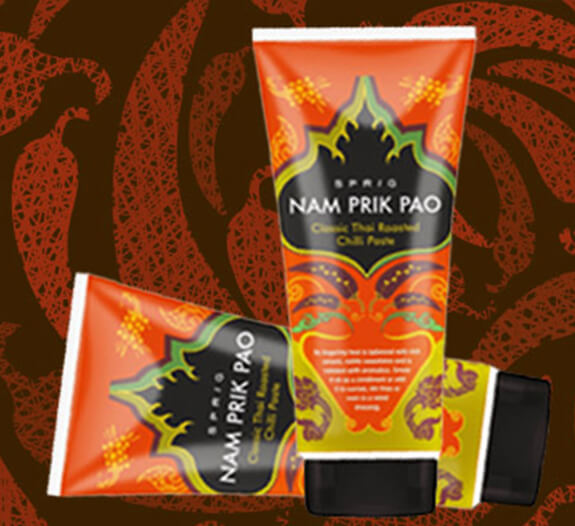

The Skin Supplement Lotion tube was re-launched to give the product a stylish, new appearance with rejuvenated appeal. Our expert graphic technicians worked with Morinda to turn this tube into a work of art. The final effect was achieved using a silkscreen printing process to capture intricate detailing, while giving the tube a high-end look with a textured feel.

The Skin Supplement Lotion tube was re-launched to give the product a stylish, new appearance with rejuvenated appeal. Our expert graphic technicians worked with Morinda to turn this tube into a work of art.

EPL has been innovating its processes relentlessly for the last 4 decades, resulting in us being the most efficient packaging company globally. We have strong innovation programs in several areas

We are committed to ensuring that we not just maintain, but build our cost & quality leadership in every market we operate in. This, we believe, is central to our success as a company.

EPL has been a thought leader in technology & manufacturing right from its very inception four decades ago. Driven by long-term thinking, EPL has always invested in the latest technologies well before time, and ahead of our competitors. This has enabled us to always provide unparalleled value to our customers. We have partnered with the world’s best machine manufacturers, who in turn treat us as preferred customers.

Our forward-thinking has led to our installing more digital printers than anybody in the world. Our factories sport the latest 12 color printers made by Gallus, the epitome of precision and decoration. Our near-zero margin printing allows effortless printing on very small surfaces with negligible wastage.

Technology is a key to competitive advantage in our industry, and EPL spares no effort to ensure that we are leading the pack in this area.